Atlas F1 Technical Writer

A poor start to their 2004 season saw the Williams team playing catch up for most of the year, only to finish on a high with their only victory in the final race. Now the BMW-powered squad want to keep their momentum going and start 2005 strongly with their new FW27. Atlas F1's Craig Scarborough offers a full analysis of the changes and features found on the new car

Last Year

Williams suffered a bad year from the first initial tests through to the B specifications released in the latter part of 2004. The initial twin tusk arrangement, along with many areas of the car, from gearbox to structures, were disappointing to the team. This failure of the team to set themselves the right targets resulted in a car on spec but off the pace of its competitors. A characteristic fightback started, backed up with staff changes: long time technical director Patrick Head assumed a new role and allowed Sam Michael to step up to the technical heads role.

Head defined the new roles: "Sam is the front line decision maker for things affecting the design and the operation of the car and I've mainly concentrated on what we call advanced development and the supporting activities i.e. the structure of the factory and the facilities we have".

Soon the sidepods were replaced with more F2003-GA style sidepods, with large chimneys, louvered outlets and undercut fronts. Then the twin tusk wing went too, saving weight and opening up scope for new wings. By the season's end the car was on the pace, but the team were far behind in the championships. Also gone by the season's end was the aerodynamicist credited with the twin tusk nose, Antonia Terzi.

New Approach

Having had several years with cars not performing out of the box, Williams' first aim was to produce a car that would be competitive from the season's start. To achieve this "High targets were set," according to Frank Williams and the team have approached these "aggressively". With Sam Michael managing the project and Gavin Fisher actually heading the design team, work progressed not only on the car's design but also working practices at the factory and wind tunnel.

In planning the new car, the problems of the old car and many of its concepts were dropped, but many familiar Williams trademarks have been retained: the old nose shape, the low sidepods, and the floor treatment. Albeit these are now very different in detail, but their philosophy has carried over despite the staff changes. What Williams have ended up with by the time of the cars launch is a car with the right level of attention paid to everything on the car, from the structures to the aero and the engine to the gearbox.

Aerodynamics

The resulting wing hangs from long drop plates and features a deep centre section and flicked up sections near the wing tips. Unlike BAR they haven't attempted to go for long chord in the centre section, but the wing has a large surface area and at its deepest section is as cambered as the height of the endplate allows. As far as the endplates themselves are concerned they are derivatives of shapes seen last year, but mounting the flap lower down instead to allow the steep wing angles seen at the launch.

Although the front bulkhead is at the same height, the region directly behind it is now very different, gone are the twin keels. Sam Michael's explains the reasoning behind the change: "The twin keels that showed small amounts of downforce gain but ensuring you had enough stiffness wasn't sufficient for us, we decided we would return to a single keel." So again Williams returned to a familiar single keel mounting only the front of the lower wishbone, with the rear pickup being mounted directly to the corner of the chassis.

The sidepod fronts themselves are undercut as with the FW26B seen last year. This flow is collected up and passed either side of the rear wing by the flip up flanking the sidepod. Unusually this flip up doesn't feature a vertical section between the rear wheels. Then Williams have aggressively lowered and shrunk the sidepods, making the rounded leading edge profile taper to wrap the exhaust pipes, while the top surface of the sidepods is low in typical Williams' fashion.

Within the sidepods the radiators remain vertical but perhaps stretch longer in the sidepods to create the required surface area. Michael described the philosophy of the new sidepod arrangement: "The main thing we tried to do there was reduce the size of the body the height of the leading edge of the sidepod. Compared to most other teams is about two inches lower. We've managed to keep that as low as possible, helped of course by the new direction of the engine with the temperatures it can run at and also there by being able to run all of the area at the top of this chimney instead of out the back."

As the floor curved up to form the diffuser, Williams have adopted a steep initial ramp and have used their trademark ramped floor to the side of the outer diffuser tunnel. Unusually, this piece of floor has a window cut in the first section of its sidewall limiting its effectiveness to produce downforce but probably acts to divert some of the air going over the floor to around the wheels.

In order to regain the lost efficiency of the rear wing Williams have installed two mid wings some way down the engine cover; they are supplemented by the shelf wing now mounted to the rear wing endplates on small extensions rather than on the (now deleted) vertical sections of flip up between the wheels.

The rear wing endplate still takes the wing loads and the FW26B detailing of a vertical slot and small slits on the top edge is still carried over. The lower beam is the simplest seen this year, the span is straight and hardly curved. Lastly the cockpit detailing has been changed, with a more pronounced snorkel on the roll structure and the cockpit side padding now sloping back down before the fin (there to meet the dimensional rules).

Engine and Mechanicals

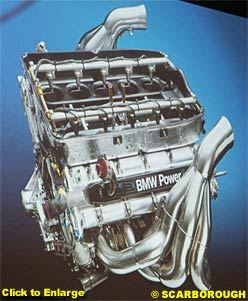

This engine was scrapped and the decision made last summer to develop the P84 and rename it as P84-5. Confusingly the team called this an all-new engine: perhaps the detail has changed but the concepts employed are retained. From the projected image of the unit on stage at the launch, the engine did look similar externally to the old unit. Over the winter Mario Theissen insisted he thought the 2004 P84 was the benchmark engine in F1 for top end power, at the same time stating it lost power at the start of 2004 only making up the deficit towards the end of the season.

Again BMW are stating power loss and reduced revs for the start of the season. This is at a time when other manufacturers are confirming their engine outputs and speeds are rising.

The gearbox was cited as one of many weak points on the FW26; this year the gearbox has been reworked fixing the "four or five" problems with it that could not be solved last year. The unit is a co-operative effort between Williams and BMW with the internals and casting being provided by BMW. It has since run extensively in a test car with out problems for around "13,500km".

Despite being in close contention for the 2003 World Championship Williams haven't produced a car that has been competitive from the start to the finish of the Championship for some time.

Last year a radical aerodynamic approach was tried to leapfrog the opposition: this and other areas of the car failed in this respect. For 2005 the team have gone back to basics and worked hard to set ambitious targets to release the most competitive car possible. While the car uses many conventional designs, it still bears a family resemblance to other Williams and abounds with detailed touches proving the team have been hard at work.

Last year a radical aerodynamic approach was tried to leapfrog the opposition: this and other areas of the car failed in this respect. For 2005 the team have gone back to basics and worked hard to set ambitious targets to release the most competitive car possible. While the car uses many conventional designs, it still bears a family resemblance to other Williams and abounds with detailed touches proving the team have been hard at work.

Replaced by Loic Bigois, the ex Prost\Minardi aerodynamicist, who had been commissioning the new wind tunnel (Williams' second). Yet there were still problems in the car only major redesigns could cure and these weren't possible in the heat of a season.

Replaced by Loic Bigois, the ex Prost\Minardi aerodynamicist, who had been commissioning the new wind tunnel (Williams' second). Yet there were still problems in the car only major redesigns could cure and these weren't possible in the heat of a season.

Williams have adopted a highly raised nose tip, featuring a reflex angle similar to the FW25 to blend it back into the line of the front of the monocoque. This has been done to allow the maximum height possible over the wing to allow for steeper wing profiles be run at a later date. Sam Michael outlined that the front wings deeply curved profile was because the raising of the outer sections of wing in the new rules move the wings "away from ground effect", adding "so the more you can work the centre part of the wing the main plane and the flap the more downforce you can generate on the front axle to make sure you can the get the aero balance required."

Williams have adopted a highly raised nose tip, featuring a reflex angle similar to the FW25 to blend it back into the line of the front of the monocoque. This has been done to allow the maximum height possible over the wing to allow for steeper wing profiles be run at a later date. Sam Michael outlined that the front wings deeply curved profile was because the raising of the outer sections of wing in the new rules move the wings "away from ground effect", adding "so the more you can work the centre part of the wing the main plane and the flap the more downforce you can generate on the front axle to make sure you can the get the aero balance required."

Williams have then created new bargeboards, following a Jordan format of one piece boards featuring splits to form three vanes, one lower vane, then a long middle vane and lastly the shorter but taller upper vane. Sitting between the new boards is a revised shadow plate, this now features a curved fence and fins at floor and step level to direct the flow off the plate and around the sidepods, the outer edge retaining the floor fin seen on the car late last year. Just as with the McLaren the whole treatment around the front of the sidepods is very integrated and intricate.

Williams have then created new bargeboards, following a Jordan format of one piece boards featuring splits to form three vanes, one lower vane, then a long middle vane and lastly the shorter but taller upper vane. Sitting between the new boards is a revised shadow plate, this now features a curved fence and fins at floor and step level to direct the flow off the plate and around the sidepods, the outer edge retaining the floor fin seen on the car late last year. Just as with the McLaren the whole treatment around the front of the sidepods is very integrated and intricate.

And indeed the chimney is huge, so much so the launch version required a "V" cut out of the winglet mounted behind it to clear the teardrop shaped duct. Yet, the duct sits on a large panel that could allow additional vents or the larger chimneys in hot conditions. The exhaust outlet is low and close to the car's centreline, but does attach to a panel that can also be enlarged to suit hotter conditions.

And indeed the chimney is huge, so much so the launch version required a "V" cut out of the winglet mounted behind it to clear the teardrop shaped duct. Yet, the duct sits on a large panel that could allow additional vents or the larger chimneys in hot conditions. The exhaust outlet is low and close to the car's centreline, but does attach to a panel that can also be enlarged to suit hotter conditions.

Unlike most teams BMW have decided to evolve their 2004 engine for the new rules. Mario Theissen speaking at the launch was far from pleased with the late rule change: "We were not happy about the short period of notice, which lead to a cost increase initially instead of a cost reduction. I would say to totally design and develop an engine you would need a period of notice of 18 moths and we didn't have that this time. One of the factors leading to BMW's unhappiness was because of an aggressive engine under development called P85 which was aimed at 800km" (one engine per weekend rules).

Unlike most teams BMW have decided to evolve their 2004 engine for the new rules. Mario Theissen speaking at the launch was far from pleased with the late rule change: "We were not happy about the short period of notice, which lead to a cost increase initially instead of a cost reduction. I would say to totally design and develop an engine you would need a period of notice of 18 moths and we didn't have that this time. One of the factors leading to BMW's unhappiness was because of an aggressive engine under development called P85 which was aimed at 800km" (one engine per weekend rules).

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 11, Issue 5

Articles

A Day in the Life

Technical Analysis: Williams FW27

Technical Analysis: Renault R25

Regular Columns

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |